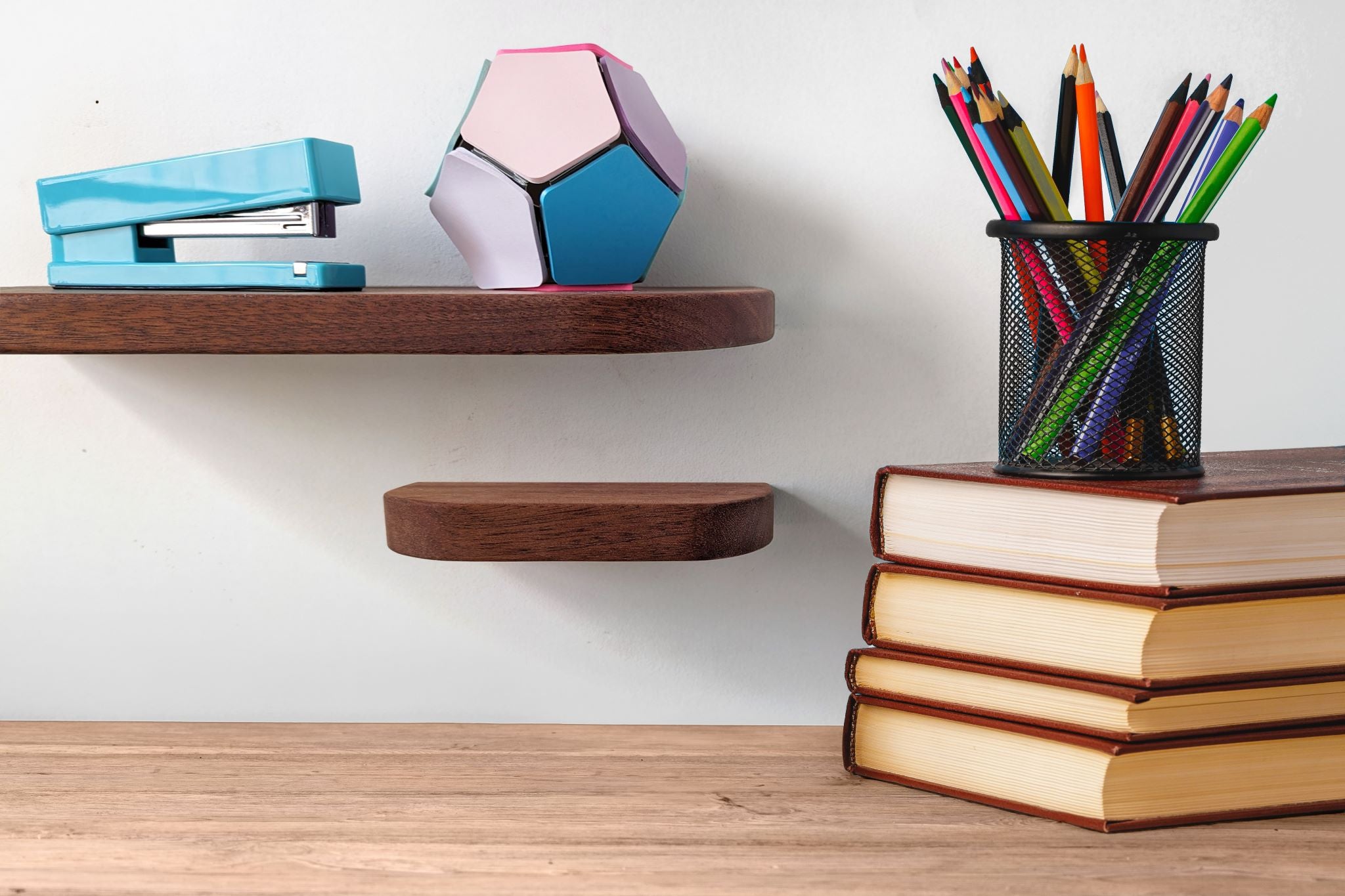

Setting up your custom shelves from NookWoodworking is pretty straightforward and surprisingly satisfying. Seriously, it’s like a mini DIY victory waiting to happen. Whether your shelves are meant to showcase your book collection or just give your plants a cozy spot by the window, let’s walk through the process together, keeping it chill every step of the way.

What You’ll Need:

First up, make sure you’ve got all the bits and pieces that came with your shelf. NookWoodworking is cool about including everything you need, but it’s always good to double-check. You’ll need the right brackets or screws that came in the box, and while you’re at it, grab a drill, level, stud finder, and pencil. These are your DIY besties for this task.

If You’ve Got The Thick Floating Shelf Brackets:

Stud Hunt: Flip on that stud finder and mark where those hidden studs are. They’re your golden ticket to a sturdy shelf.

Bracket Time: Hold up the bracket to where you’ve made your marks and drill it securely into the studs.

Shelf Slide: Pop the shelf onto the bracket and nudge it until it’s snug against the wall.

T-Brackets for Sleeker Shelves:

Bracket Prep: Loosen the bracket on the shelf so you can mark the screw spots on your wall.

Drill Baby Drill: After you’ve marked where the screws will go, drill some pilot holes, jam in those wall anchors, and fix the bracket onto the wall.

Snap the Shelf On: Get the shelf back onto the bracket, wiggle it till it’s level, and you’re all set!

Twist-On Style for An Easy Win:

Mark it Up: Decide where the shelf will go, mark it, drill a hole, and pop in the anchor.

Twist and Shout: Just twist the shelf into place. Okay, maybe don’t shout, but a little victory dance never hurt.

Keep It Level:

Make sure everything looks straight with your level. If the shelf wobbles or looks a bit wonky, you might need to adjust a bit with some shims or even a bit of electrical tape around the bracket for a tighter fit.

Wrapping Up:

And there you have it! Your very own custom shelf setup, ready to take on whatever you want to display. The beauty of these shelves from NookWoodworking isn’t just in how awesome they look but also in the satisfaction of hanging them up yourself. It’s a little touch of DIY that adds personality to your space. If you hit a snag or just want to geek out over home decor, NookWoodworking has some solid guides and a friendly team ready to help out.